Shenanigans

Well-Known Member

Hi All,

Normally I do BIAB in a 8 gallon electic kettle and sparge with about 2.5 gallons.

With about 70% efficiency this works fine to get 5 gallon beers up to an OG of about 1.080.

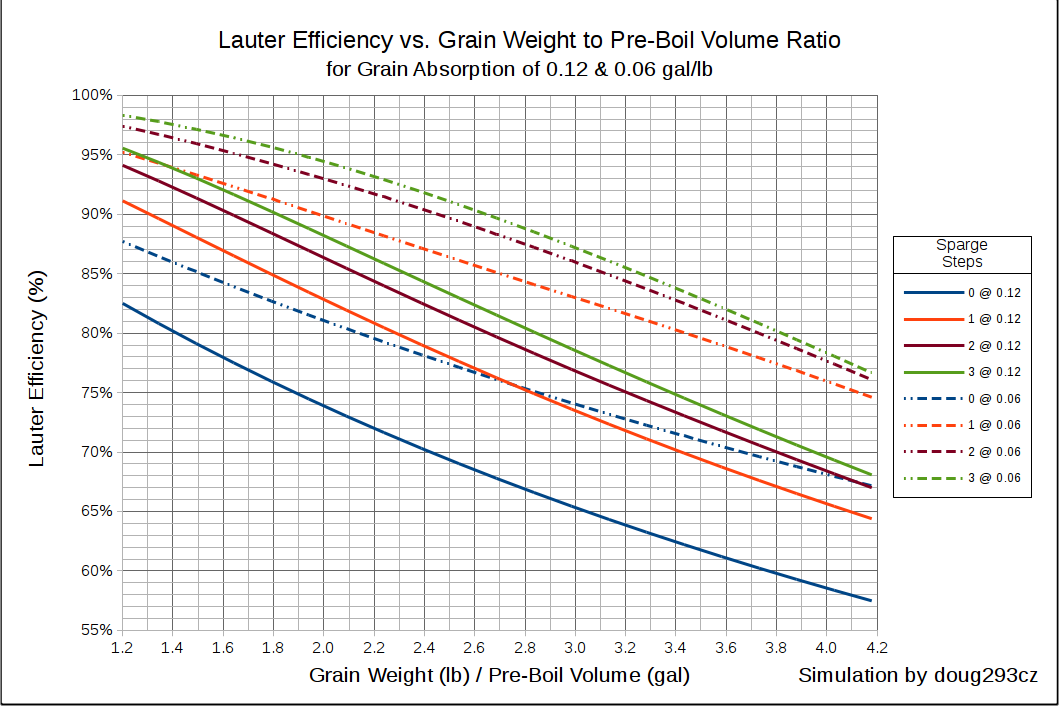

However if I want to aim for something with an OG around 1.100 then I have to do a no sparge mash in a 13 gallon cooler. This works fine, I have the process nailed and hit my numbers and volumes but the efficiency goes down to 50 to 55%. I could probably increase the efficiency by sparging but it would take a while for me to nail that process. So for now I will continue to do it this way.

I see in Beersmith that color of the worth shoots up for the same OG as the efficiency goes down. This indicates that the efficiency of the extraction from the malts that need to be mashed take a bigger hit than the malts that don't need to be mashed resulting in the ratio of mash sugars to non-mash sugars (or roasted) going up which increases the color. This can be a problem when trying to clone a beer because a tried a trusted recipe is probably developed with a mash efficiency of greater than 70%.

My question is, is there some way to calculate how to change the ratio of non-mash to mash malts so that you end up with a similar beer from a 50% system to one with a higher efficiency or am I overreacting and it's not really a problem?

Thanks

Normally I do BIAB in a 8 gallon electic kettle and sparge with about 2.5 gallons.

With about 70% efficiency this works fine to get 5 gallon beers up to an OG of about 1.080.

However if I want to aim for something with an OG around 1.100 then I have to do a no sparge mash in a 13 gallon cooler. This works fine, I have the process nailed and hit my numbers and volumes but the efficiency goes down to 50 to 55%. I could probably increase the efficiency by sparging but it would take a while for me to nail that process. So for now I will continue to do it this way.

I see in Beersmith that color of the worth shoots up for the same OG as the efficiency goes down. This indicates that the efficiency of the extraction from the malts that need to be mashed take a bigger hit than the malts that don't need to be mashed resulting in the ratio of mash sugars to non-mash sugars (or roasted) going up which increases the color. This can be a problem when trying to clone a beer because a tried a trusted recipe is probably developed with a mash efficiency of greater than 70%.

My question is, is there some way to calculate how to change the ratio of non-mash to mash malts so that you end up with a similar beer from a 50% system to one with a higher efficiency or am I overreacting and it's not really a problem?

Thanks