I've converted my system over to all electric and I'm down to getting the right 240v controller. I have a 3v system with a HERMS. After extensive research I'm thinking the Auber Instrument's Brew Buddy II is the way to go. I need user feed back before making the purchase. Anyone with experience using a Brew Buddy please advise. Is it worth the $1500 or is there a better alternative?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brewery controller

- Thread starter T Murph

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

If you're going with the "II" version, I assume you plan to run both elements at the same time. Otherwise you can go with the 30amp version and have the selector switch to choose which element gets fired up. I'm not aware of a more feature rich controller for that money unless you're willing to use a microcomputer based system like UniFlex Control System – BruControl That runs about $1200 with the options you'd need and you'd need a computer monitor and whatnot on top of that.

Thanks for responding Bobby. Yes I do plan on running two vessels at the same time. Also two pumps. I've reviewed other options but I haven't found anything that appears to fill my needs better than the Brew Buddy II. If I'm wrong please advise.

Zemillard90

Well-Known Member

- Joined

- Jun 17, 2018

- Messages

- 59

- Reaction score

- 45

I would throw the Blichmann Brewcommander into the mix. You would need two of them as a single unit can run one kettle, however the price would be roughly $800 for both. A single unit can run one element and one pump (not sure how many elements you have but you can add a module for about $100 I believe). I have one running a single element for my 3v (I just switch from heating the hlt to the bk as I don't need them running at the same time). I have been a big fan since starting to use this for over a year now. Lots of great features (delay start, herms offset, different brew profiles, etc.) and takes up very little space comparatively.

You can do BruControl (without the UniFlex) for a lot less than $1200, but in the end you can expand over time. You need BruControl software, an Arduino Mega, some SSRs and a Windows Computer. In addition the wiring and elements, but you would need that with any system.

I would throw the Blichmann Brewcommander into the mix. You would need two of them as a single unit can run one kettle, however the price would be roughly $800 for both. A single unit can run one element and one pump (not sure how many elements you have but you can add a module for about $100 I believe). I have one running a single element for my 3v (I just switch from heating the hlt to the bk as I don't need them running at the same time). I have been a big fan since starting to use this for over a year now. Lots of great features (delay start, herms offset, different brew profiles, etc.) and takes up very little space comparatively.

Ty, I had ordered a blinchman controller back in May but they can't seem to produce it. They are now saying they will be shipping in September. Got tired of waiting and did some research and realized I want a more complete controller. I want to run my HLT, BK, HERMS via HLT and two pumps with one capable controller. So far I haven't found anything more accommodating than the Brew Buddy II. I'm just searching for additional options.I would throw the Blichmann Brewcommander into the mix. You would need two of them as a single unit can run one kettle, however the price would be roughly $800 for both. A single unit can run one element and one pump (not sure how many elements you have but you can add a module for about $100 I believe). I have one running a single element for my 3v (I just switch from heating the hlt to the bk as I don't need them running at the same time). I have been a big fan since starting to use this for over a year now. Lots of great features (delay start, herms offset, different brew profiles, etc.) and takes up very little space comparatively.

You could have gone with a BCS but I am not sure if they are going to be available again. While not turnkey, BruControl (Demo – BruControl) is the way we went. It is a very good system for personation of your Brew Process and can be expanded.

I’m happy with my brew commander. I was also considering the Cube when I bought it.,

https://www.auberins.com/index.php?main_page=product_info&cPath=64_65&products_id=832

https://www.auberins.com/index.php?main_page=product_info&cPath=64_65&products_id=832

Any of the single vessel controllers would need to be doubled up to heat both the HLT and the BK simultaneously and it slightly complicates the supply circuitry because it would require two separate 30 amp feeds instead of a single 50 amp. That would be the case with the BrewCommanders if you could ever find them in stock again.

Plenty of my customers use a single vessel controller on a 3 vessel and just swap the power cable and probe cable into the controller at the beginning of the boil phase. It saves quite a bit of money if the budget is the first priority.

Software vs. tactile industrial control types really comes down to how you feel about computers and software vs buttons and lights. I can't comment on the stability of all microcomputer/software systems but I demoed a piece of gear running BrewPi and it crashed more times than I would permanently subject myself to.

I just got in a Brew Buddy II yesterday for a customer build and it looks great. I already know the EZboil brains are very good compared to other PIDs so you can't go wrong there. Keep in mind that it uses a relatively rare locking input connector so get that from Auber or elsewhere online rather than try Home Depot.

Plenty of my customers use a single vessel controller on a 3 vessel and just swap the power cable and probe cable into the controller at the beginning of the boil phase. It saves quite a bit of money if the budget is the first priority.

Software vs. tactile industrial control types really comes down to how you feel about computers and software vs buttons and lights. I can't comment on the stability of all microcomputer/software systems but I demoed a piece of gear running BrewPi and it crashed more times than I would permanently subject myself to.

I just got in a Brew Buddy II yesterday for a customer build and it looks great. I already know the EZboil brains are very good compared to other PIDs so you can't go wrong there. Keep in mind that it uses a relatively rare locking input connector so get that from Auber or elsewhere online rather than try Home Depot.

Golddiggie

Well-Known Member

I went with the Electric Brewing Supply (50amp/double batching) panel when it came time to get a single panel to control my electric kettles. This is their new design, which includes provisions for a steam condenser lid pump. It also has controls for two March/Chugger type pumps (wort and water). I went with the 50amp version for when I want to do a double batch. IIRC, you can get the same panel setup for a single batching (single element powered at a time, 30amp needed) if you want.

Personally, I'm glad I went with this panel. It's easy to use, well laid out and just works. IMO, if you ever think you'll want to double batch, or have the BK and HLT elements running at the same time, get the 50amp panel. I like having the additional capability for when I want to use it than have to monkey around with things later to make such a setup work. "Better to have and not need, then need and not have."

Personally, I'm glad I went with this panel. It's easy to use, well laid out and just works. IMO, if you ever think you'll want to double batch, or have the BK and HLT elements running at the same time, get the 50amp panel. I like having the additional capability for when I want to use it than have to monkey around with things later to make such a setup work. "Better to have and not need, then need and not have."

I have always been subject to an overly strong sense of 'I want it my way'. (I imagine this to be common among home brewers)

I spent a looong time trying to find a controller that did it my way before I gave up. I looked up some electrical wiring diagrams to gain a basic understanding, researched the internal components, drew up a diagram of how the components were going to be wired, showed it to a brother with HVAC/electrical experience, modified my plans as per his input, bought the components (mostly Auber Instruments, some Amazon) and built one myself for <$500. If I added in my time at the rate I am paid for work the cost is probably closer to $5000 but I enjoyed the project from start to finish and learned some new skills.

I spent a looong time trying to find a controller that did it my way before I gave up. I looked up some electrical wiring diagrams to gain a basic understanding, researched the internal components, drew up a diagram of how the components were going to be wired, showed it to a brother with HVAC/electrical experience, modified my plans as per his input, bought the components (mostly Auber Instruments, some Amazon) and built one myself for <$500. If I added in my time at the rate I am paid for work the cost is probably closer to $5000 but I enjoyed the project from start to finish and learned some new skills.

And that is why I'm looking to purchase a professionally build controller. I'm moderately experienced with electricity but the way I see it, I want something out of the box that is complete, ready to work and backed by a guarantee. I do however admire your dedication and skill to your hobby.I have always been subject to an overly strong sense of 'I want it my way'. (I imagine this to be common among home brewers)

I spent a looong time trying to find a controller that did it my way before I gave up. I looked up some electrical wiring diagrams to gain a basic understanding, researched the internal components, drew up a diagram of how the components were going to be wired, showed it to a brother with HVAC/electrical experience, modified my plans as per his input, bought the components (mostly Auber Instruments, some Amazon) and built one myself for <$500. If I added in my time at the rate I am paid for work the cost is probably closer to $5000 but I enjoyed the project from start to finish and learned some new skills.

Golddiggie

Well-Known Member

For me, getting a panel made by someone who KNOWS what they're doing was worth the cost. I didn't need to worry about making incorrect connections, or having something not tight enough inside (as put in another thread) causing fires or anything. Plus I wanted it ready to use sooner than I could have put it together. Especially with how little 'free time' I have after work and everything else. Hell, I have projects still waiting to be finished that I started over a year ago.I have always been subject to an overly strong sense of 'I want it my way'. (I imagine this to be common among home brewers)

I spent a looong time trying to find a controller that did it my way before I gave up. I looked up some electrical wiring diagrams to gain a basic understanding, researched the internal components, drew up a diagram of how the components were going to be wired, showed it to a brother with HVAC/electrical experience, modified my plans as per his input, bought the components (mostly Auber Instruments, some Amazon) and built one myself for <$500. If I added in my time at the rate I am paid for work the cost is probably closer to $5000 but I enjoyed the project from start to finish and learned some new skills.

When I get my next size up system, I'll make sure it either comes with a control panel, or order one to arrive either before the system, or soon after.

I do like your controller however I still think the Brew Buddy II will fit my system better for some $400 less. The BS II has a fourth temperature probe to allow monitoring inlet and outlet temps of the HERMS coil. Thanks for your post. That is a controller that I had not seen before. And since I don't know yet which one I will go with, that is a viable option.I went with the Electric Brewing Supply (50amp/double batching) panel when it came time to get a single panel to control my electric kettles. This is their new design, which includes provisions for a steam condenser lid pump. It also has controls for two March/Chugger type pumps (wort and water). I went with the 50amp version for when I want to do a double batch. IIRC, you can get the same panel setup for a single batching (single element powered at a time, 30amp needed) if you want.

Personally, I'm glad I went with this panel. It's easy to use, well laid out and just works. IMO, if you ever think you'll want to double batch, or have the BK and HLT elements running at the same time, get the 50amp panel. I like having the additional capability for when I want to use it than have to monkey around with things later to make such a setup work. "Better to have and not need, then need and not have."

Golddiggie

Well-Known Member

I don't think the additional sensor for the HERMS outlet is really of any value. Since it matters, more, what the MT temperature is.I do like your controller however I still think the Brew Buddy II will fit my system better for some $400 less. The BS II has a fourth temperature probe to allow monitoring inlet and outlet temps of the HERMS coil. Thanks for your post. That is a controller that I had not seen before. And since I don't know yet which one I will go with, that is a viable option.

I do like how easy it is to talk with Electric Brewing Supply. I had several emails/conversations around the panel both before I placed the order and after. Both before and after it arrived. VERY helpful for getting things setup correctly.

If ebrewsupply updates their 360 panel to include provisions for the Spike SCL (or a SCL pump), I'll be considering getting that for my next panel.

Reach out to Spike and/or SS Brew Tech to find out.How do the spike/Ssbrewtech controllers compare to the Auber controllers as far as quality of components and longevity of parts?

IME, Spike offers really solid products. SSBrew Tech is also good stuff. I haven't had any powered items from SSBrew Tech so far, but my Spike+ kettles and fermenters are high quality. I would imaging the same methodology would follow through everything they sell. Of course, you cannot get JUST the control panel from Spike (I asked). It comes as part of their systems.

RufusBrewer

Well-Known Member

Now that you decided you want the ability to run two elements at the same time, and you want a turn key ready to go solution, your choices are much fewer.

Seems to me, the difference between possible systems, will come down to the interface of the PID. Choose the system that uses the PID you prefer. That is where your decision will manifest in brew day happiness or frustration and/or regret.

Pump On/Off switch? Those are going to about the same. But working with a PID and temp probe, that is what counts.

I suggest you downlaod manuals for the systems you are considering. read through them and get familiar with what each manufacturer has to offer.

One thing I can tell you about menu trees. Once you use them and get familiar with the system you have, it becomes second nature. Also laminate a copy of the menu tree and keep them near by as a refernece. After a few uses, you will not need it.

Seems to me, the difference between possible systems, will come down to the interface of the PID. Choose the system that uses the PID you prefer. That is where your decision will manifest in brew day happiness or frustration and/or regret.

Pump On/Off switch? Those are going to about the same. But working with a PID and temp probe, that is what counts.

I suggest you downlaod manuals for the systems you are considering. read through them and get familiar with what each manufacturer has to offer.

One thing I can tell you about menu trees. Once you use them and get familiar with the system you have, it becomes second nature. Also laminate a copy of the menu tree and keep them near by as a refernece. After a few uses, you will not need it.

Golddiggie

Well-Known Member

I'm using one of these secured to the back of my panel (with how it's mounted, I can do that) to hold the manual.

https://www.amazon.com/gp/product/B07GMZDDGJ

I also have one for the glycol chiller information as well as above each fermenter with the recipe sheet/printout. Those are also labeled so that even if they get swapped, I can see which is which. Not that I'd forget with only two fermenters, but starting the method now makes it easier for when I have more.

https://www.amazon.com/gp/product/B07GMZDDGJ

I also have one for the glycol chiller information as well as above each fermenter with the recipe sheet/printout. Those are also labeled so that even if they get swapped, I can see which is which. Not that I'd forget with only two fermenters, but starting the method now makes it easier for when I have more.

How do the spike/Ssbrewtech controllers compare to the Auber controllers as far as quality of components and longevity of parts?

The SSBT controllers seem to have all the same typical components, including basic PIDs, and have spent most of the R&D on making a unique enclosure for it.

The Spike controller is built by eBrewsupply.

Other than the Auber, none of the panels use the Auber EZboil brains and they are significantly better than all the PIDs I've used. You won't appreciate the functional differences until you brew on them and "get it".

The SSBT controllers seem to have all the same typical components, including basic PIDs, and have spent most of the R&D on making a unique enclosure for it.

The Spike controller is built by eBrewsupply.

Other than the Auber, none of the panels use the Auber EZboil brains and they are significantly better than all the PIDs I've used. You won't appreciate the functional differences until you brew on them and "get it".

I’ve got the full 3v system from Ssbrewtech. I really like it. I was just more curious about the quality of the components used. I’m not a fan of their customer service. They do respond via email, but it is generally a cookie cutter response that is usually common sense stuff I’ve spray tried… requiring at least one or more follow up emails. I’m convinced I know more about the menu tree inside the controller at this point than they do.

Thanks for the the reply Bobby. It’s good to know that I should get some longevity out of it knowing it has quality parts. I think I paid 1300 for the 3v controller when I bought it.

MightyOz

Local Storm Brewing

I purchased a Blichmann Brewcommander 240v to brew while I built my UNICON Brucontrol panel from scratch, has been a grand adventure and I have an open ended panel that has room to grow in my automation journey. I started with a $75 Harbor Freight tool cabinet. My Brewcommander is collecting dust since I got my UNICON up and running and now I am looking at expanding it to controlling fermentation and serving using Brucontrol. I guess my point is Brucontrol will go in any direction you want without being locked into a single configuration which you will easily outgrow if you get the process control automation bug!

RufusBrewer

Well-Known Member

I guess my point is Brucontrol will go in any direction you want without being locked into a single configuration which you will easily outgrow if you get the process control automation bug!

Impressive, the OP is looking for a turnkey solution, not a project.

Fr8Dog

Active Member

- Joined

- Sep 12, 2020

- Messages

- 38

- Reaction score

- 49

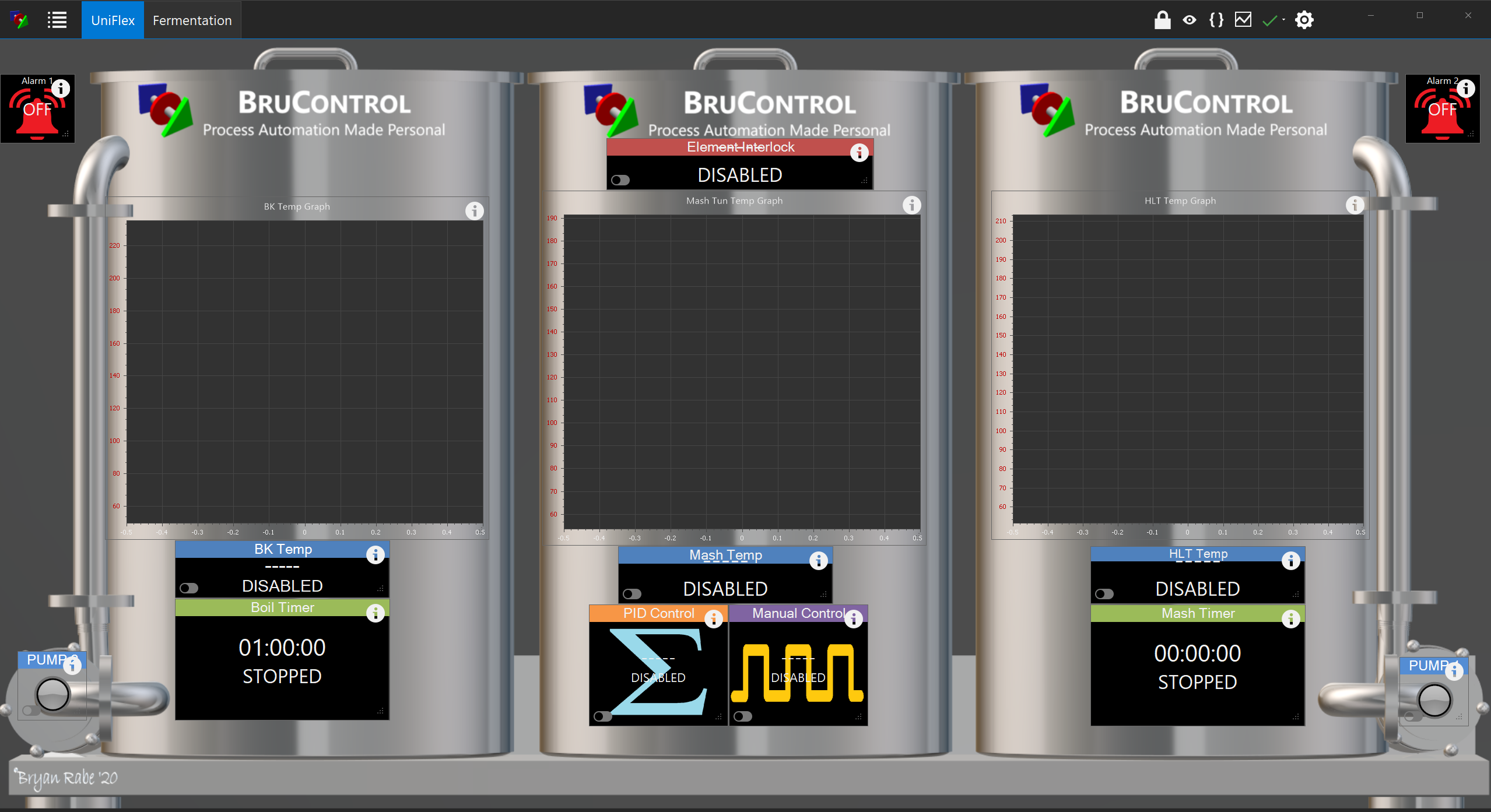

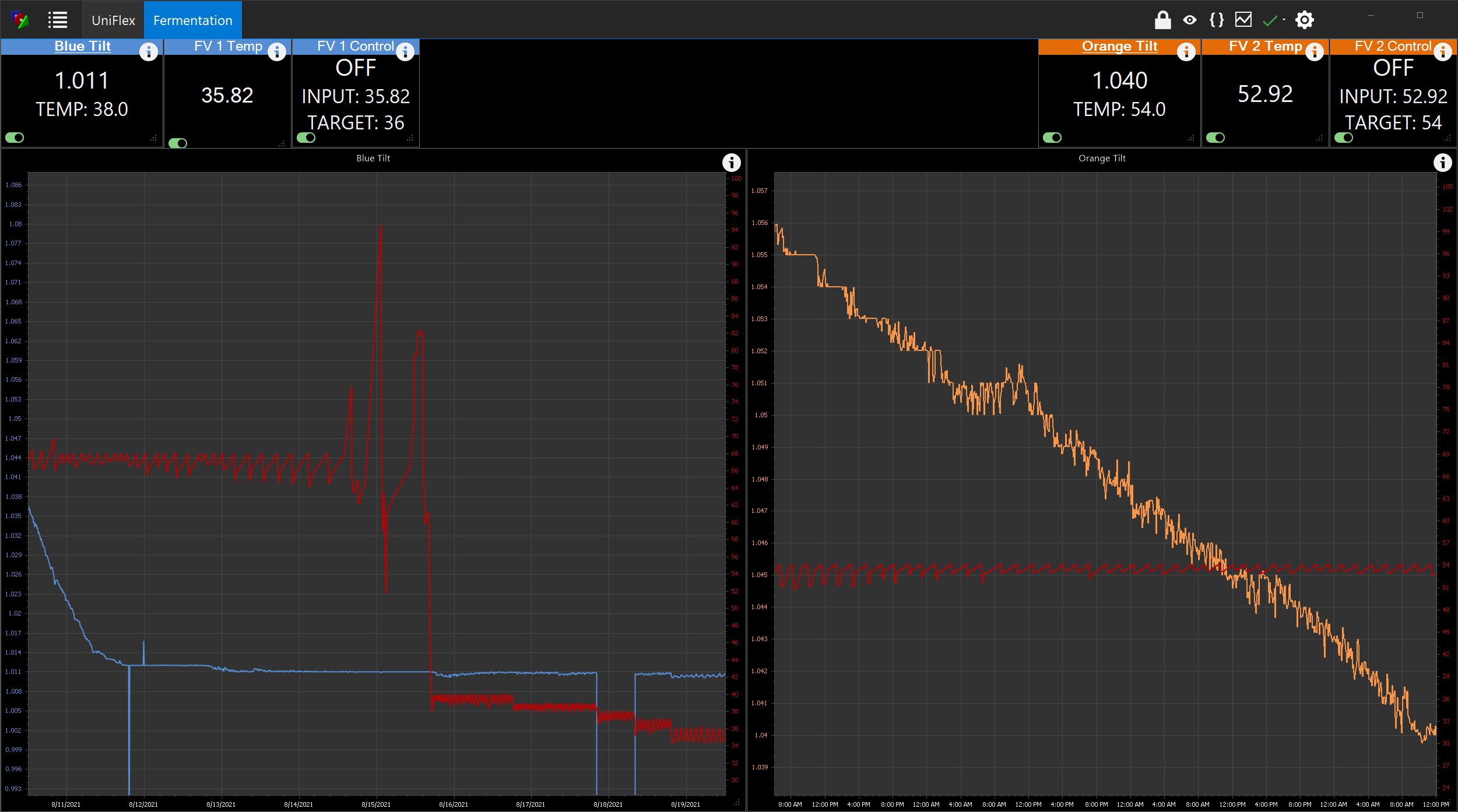

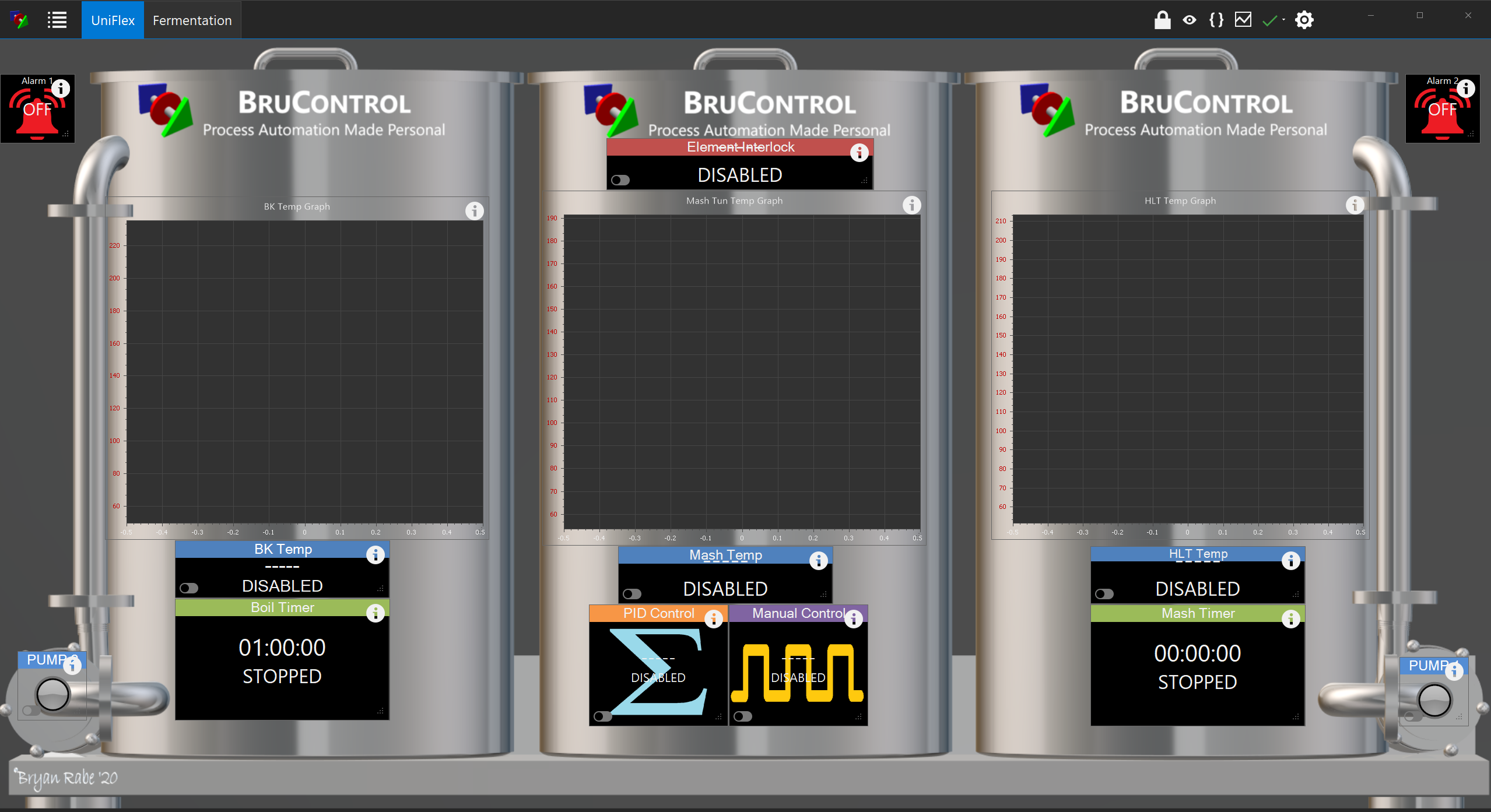

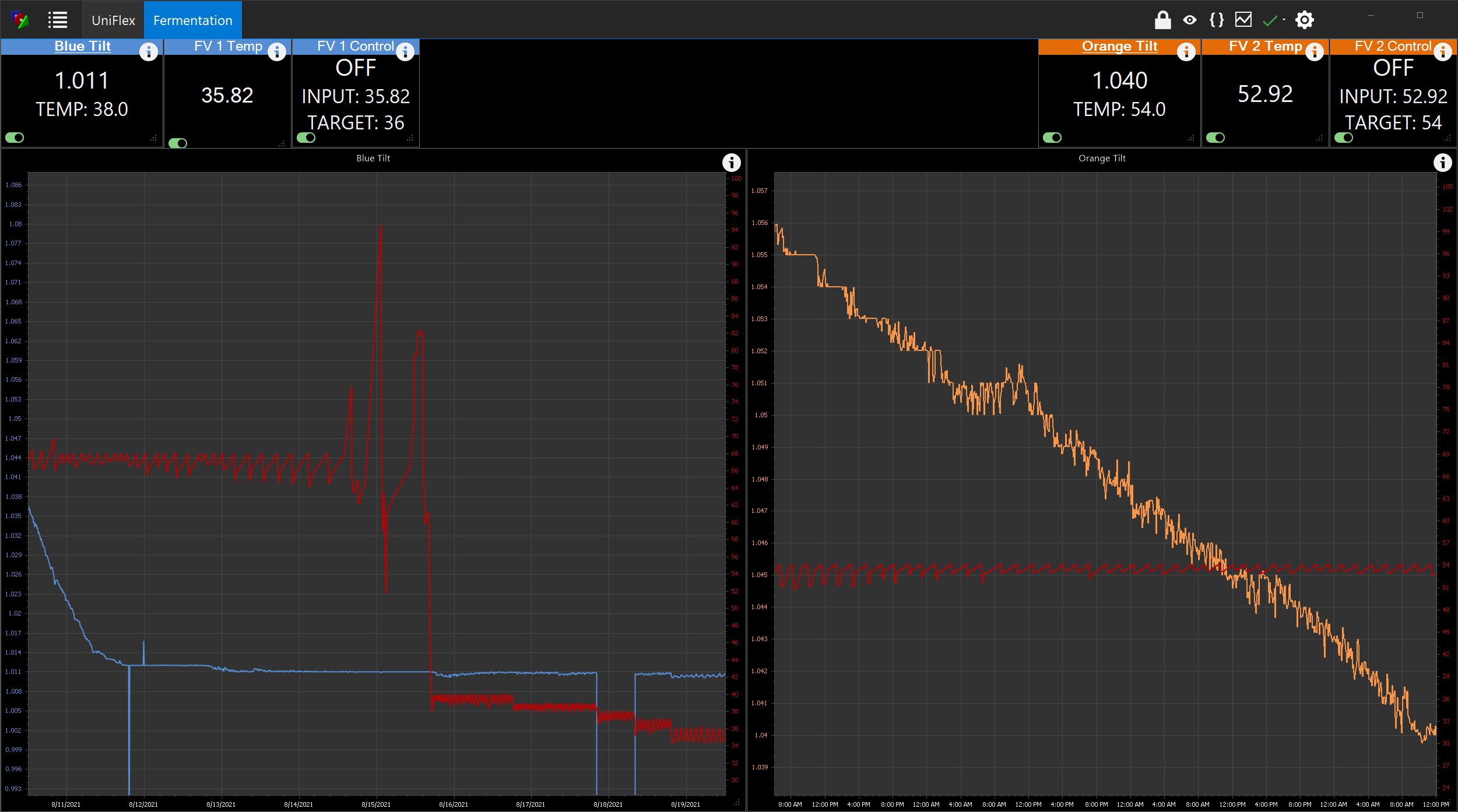

I went with a turn key version of BruControl, the UniFlex. It controls my brew rig and my fermenters. I have a 3V HERMs system and two jacketed 15 gallon fermenters. BruContol runs my Riptide pumps and the glycol pumps in the Penguin chiller as well as reading the Tilts. The software runs on my desktop in my office. On brew day I project the desktop screen to my touchscreen laptop. The laptop is used in the garage to control the brew rig. Once the wort is in the fermenter the fermentation is controlled by BruControl running in the background on my desktop. The UniFlex is mounted to the wall on DIN rails in my garage between the SS conicals. That keeps it close enough to read the Tilts through the double SS walls of the fermenters and it is able to connect to my wifi network.

It was very simple to setup and worked right out of the box.

It was very simple to setup and worked right out of the box.

I bought the Brew Buddy II panel this year and have brewed with it about 5 times. Worked great right out of the box. Couldn’t be happier.

...want to sell that Brew Commander?I purchased a Blichmann Brewcommander 240v to brew while I built my UNICON Brucontrol panel from scratch, has been a grand adventure and I have an open ended panel that has room to grow in my automation journey. I started with a $75 Harbor Freight tool cabinet. My Brewcommander is collecting dust since I got my UNICON up and running and now I am looking at expanding it to controlling fermentation and serving using Brucontrol. I guess my point is Brucontrol will go in any direction you want without being locked into a single configuration which you will easily outgrow if you get the process control automation bug! View attachment 739549

Similar threads

- Replies

- 1

- Views

- 576

- Replies

- 8

- Views

- 2K

- Replies

- 2

- Views

- 894

- Replies

- 7

- Views

- 608